The textile finishing activity carried out by the Group is a point of reference in Europe for companies in the home furnishing, linen, hotel and contract sectors. The solid production experience, the dyeing and process know-how. The operational flexibility and the wide range of machines for the

production of large quantities. We finish, on behalf of third parties, more than 50 million square metres per year of cotton, linen, viscose and mixed fabrics such as canvases, smooth satins and jacquards, quilts and technical fabrics.

Sectors of application

Fabric for

home linens

Fabric for

the hospitality

Fabric for

the contract

Fabric for

furniture

Technical

fabric

For over 100 years we have been finishing fabrics for the furniture, household linen, hotels and contract sectors.

SATTA E BOTTELLI is a historic factory founded in 1921. The acquisition by the MARTINELLI GINETTO Group has marked its relaunch, with a significant renewal of production and the development of the skills acquired in over 100 years of activity at the service of the best Italian and European companies.

Solutions

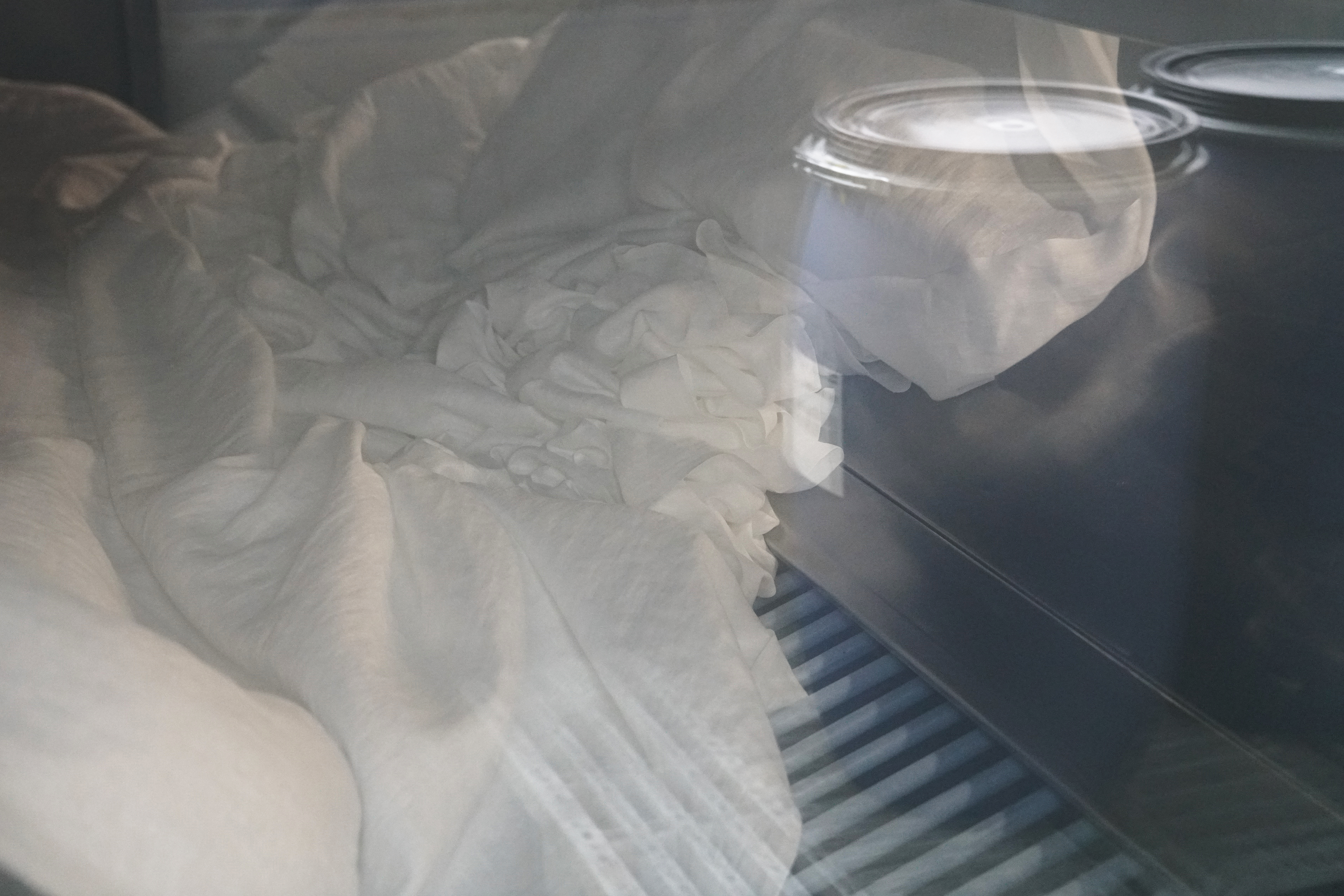

Bleaching

It generates the whitening of the fibres and the removal of impurities allowing for a clean base and constant and optimal white areas for the next phases of dyeing or printing.

Mercerising

It gives shine and absorbency to the fibre and eliminates dead cotton. It increases the dyeing affinity of the fibre and improves dimensional stability.

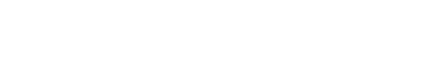

Dyeing

It gives the textile product a certain colour that allows for the customization of the product. Depending on the type of fibre, the intended use and the solidity to be obtained, different application methods and dyeing processes are used (reactive, indanthrene, dispersed).

Abrasion and Calendering

The abrasion generates a superficial abrasion to the fabric in order to obtain a "velvety" effect, that confers softness and a velvety appearance.

The calendaring is a phase in which the fabric is subjected to either hot or cold pressure (ironed effect), to give the fabric shine and feel.

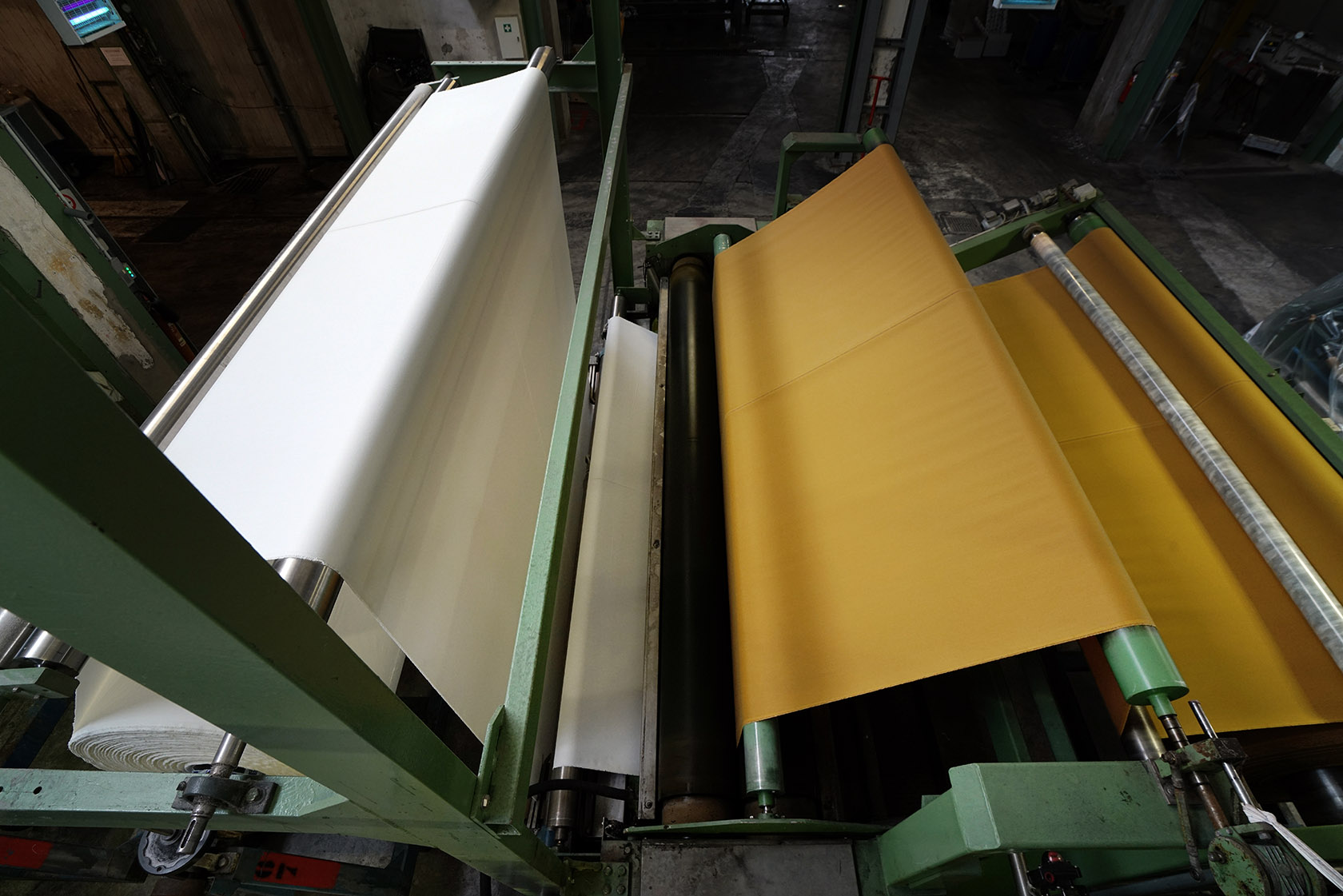

Swelling and relaxation

Fabric swelling treatment for soft, wrinkled, "shabby chic" and stone washed effects.

Sanforizing

It improves the dimensional stability of the fabric when washing, subjecting it to both mechanical and thermal compaction.